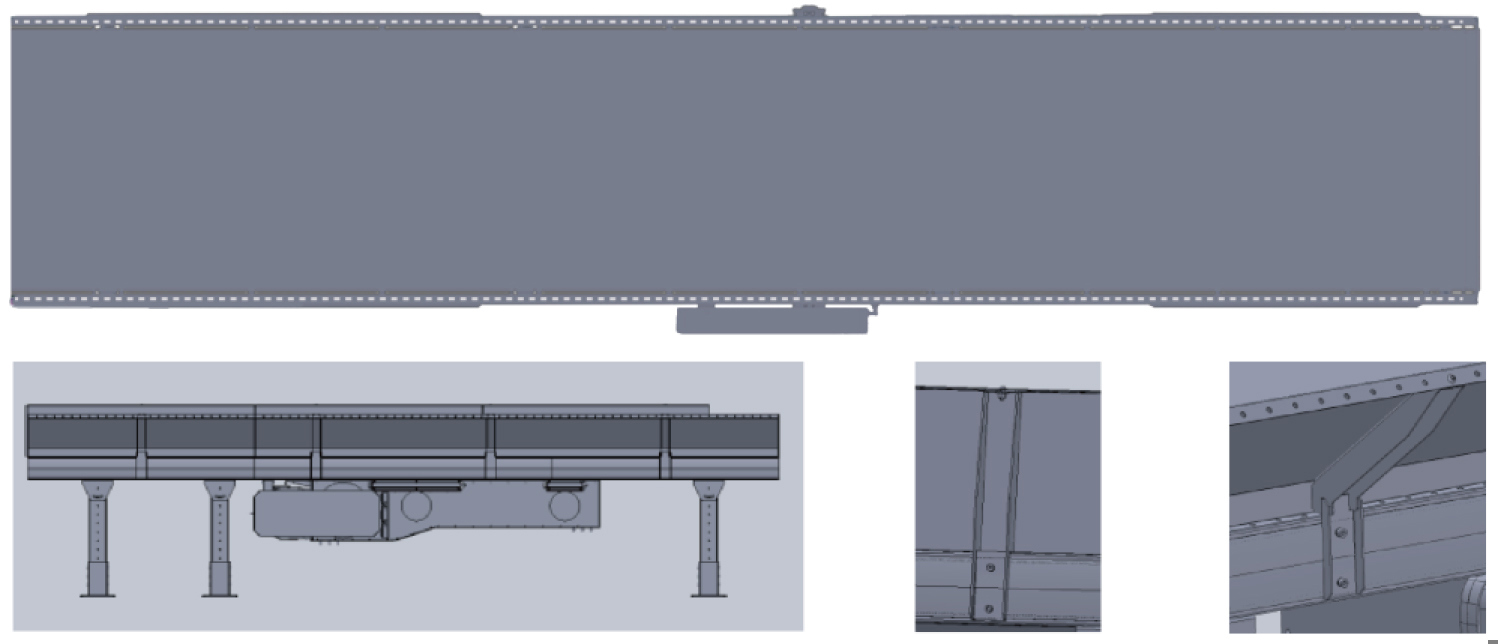

Patented rolling technology for fuselage, leg frame, side plate and support plate, fully screw connection is installed to reduce welding parts and paint baking parts. The side space of the fuselage can meet the side arrangement of power line and control line and reduce the line groove. The body of the minimum equal clearance square hole, so that the tray roller can be freely arranged installation, reduce the design workload. Special triangular reinforcing bar makes the frame become firm.

Product features

Patented rolling technology for fuselage, leg frame, side plate and support plate, fully screw connection is installed to reduce welding parts and paint baking parts.

The side space of the fuselage can meet the side arrangement of power line and control line and reduce the line groove.

The body of the minimum equal clearance square hole, so that the tray roller can be freely arranged installation, reduce the design workload.

Special triangular reinforcing bar makes the frame become firm.

The lower roller is installed in the height of the fuselage and combined with the dense square hole at the bottom edge of the fuselage to install the safety soundproof bottom plate at any time.

The drive seat can be installed at any position under the fuselage, which is convenient for use and maintenance.

Both sides of the baffle plate including the inclined baffle plate to realize the rolling process and free installation, reduce the reinforcement diameter of the baffle welding.

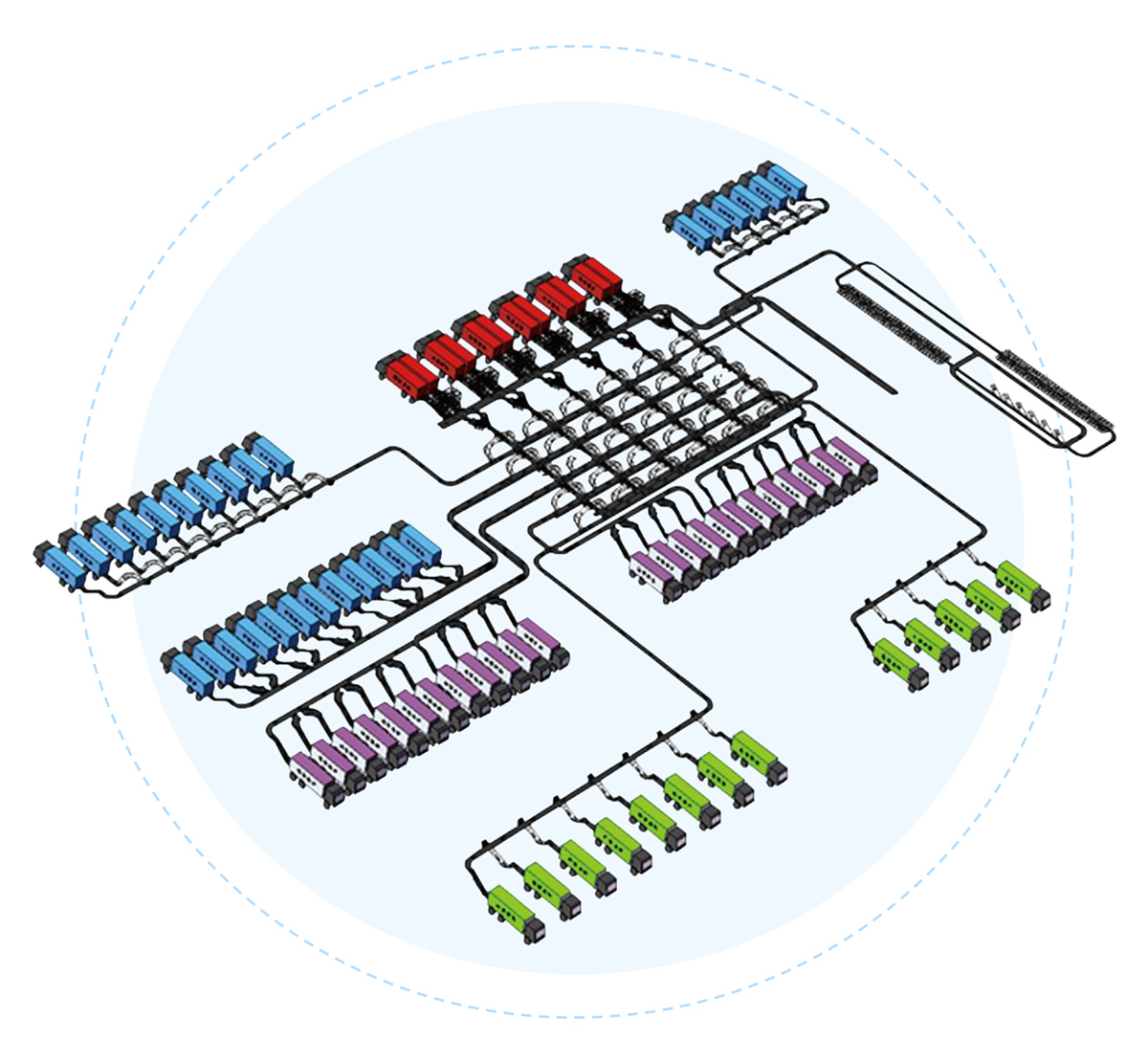

Applicable to the four aspects of the logistics industry

|

|

|

|

|

Express logistics operation center. Labor-saving equipment for cargo trucks |

Automatic detection, identification and sorting of cargo barcode |

Research and development of intelligent sorting equipment Production and sales services |

Overall project planning and integration |

Customer case