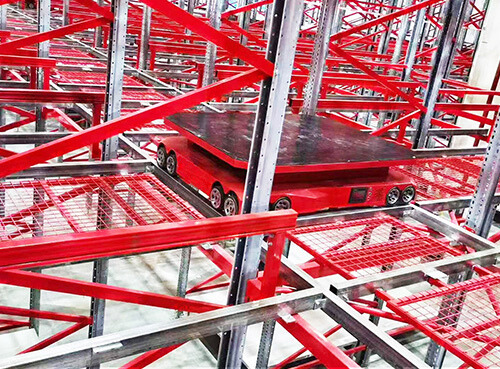

Multi-Level-Shuttles vehicle storage & retrieval system

Optimizes existing warehouse space and improves handling capacity nearly by 10 times compared with traditional warehouse

Heavy-load 4-direction shuttle vehicle storage & retrieval system

Realizes the demand for large-scene, long- distance, high-speed, and high-precision intelligent logistics and reduces 50% labor force.

Miniload system

Reduces the distance for handling materials back and forth, maximizes the storage space and Improves working efficiency

Pallet conveyor system

Featured by high efficiency flexibility and comfort, it can realize a very high handing speed in the warehouse, to as to keep material flow at an optimal speed.

Box-type conveyor system

Efficiently transport products in turnover box, carton and other packages and realize efficient conveying with standardized design and in different combinations.

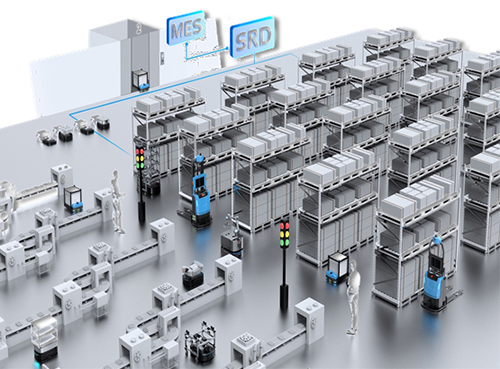

AGV handling system

Strong recognition capabilities and positioning precision. Path conversion for guiding mode is convenient and flexible, and logistics system setting is flexible.

Vertical conveyor system

The system is featured by is small floor area, a simple and practical structure, low noise, easy installation and maintenance and materials can be conveyed upward and downward.

Inventory optimized

Multiple dimensions and strategies enable more reasonable warehousing and ex-warehouse, and improve warehouse operation and utilization rate of storage space

Manual operation saved

The assistance of the informatized intelligent system can reduce manual operation and improve accuracy

Management system improved

Process visualization and warehousing operation data support the optimization of management system

Productivity increased

Informatization helps improve efficiency