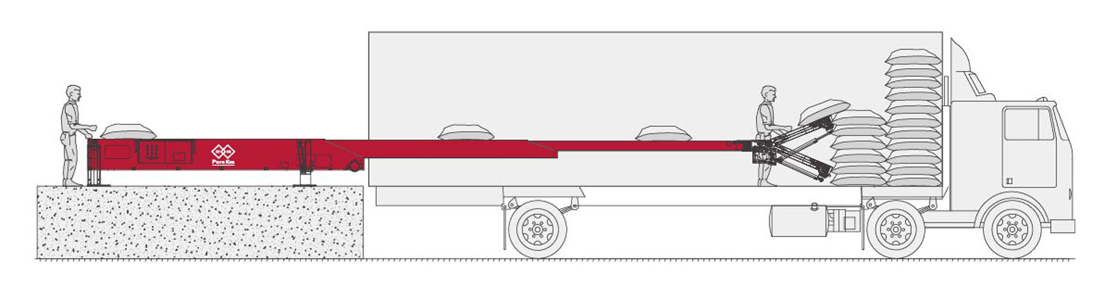

Telescopic belt conveyor (telescopic loading machine) is widely applied in various industries, it could be freely adjusted the working length in need during the working time. The height of extension end could be adjusted as well to match other sections of package loader. The bidirectional working allows the automatic loading and unloading of material production, and package transferring.

|

Product overview

Telescopic belt conveyor (telescopic loading machine) is widely applied in various industries, it could be freely adjusted the working length in need during the working time. The height of extension end could be adjusted as well to match other sections of package loader. The bidirectional working allows the automatic loading and unloading of material production, and package transferring.

Product features

|

|

Swing arm type telescopic belt conveyor

Wide application, excellent performance

As an expert and leader in domestic fast loading and unloading equipment, products are widely used in e commerce express logistics center and factory logistics center to help increase the load capacity, reduce loading and unloading costs, and improve the working environment. Faced with vans of different specifications, all have corresponding products and provide perfect solutions.

Good adaptability, reliability and durability

He equipment can be freely expanded and extended in the direction of length. According to the requirements of loading and unloading, the operator can adjust the machine to the most comfortable distance, reduce labor intensity, improve work efficiency, and conform to ergonomic design. Rich configuration options to meet your different loading and unloading requirements, the product is easy to operate, safe, reliable, durable.

LED lights

24 volt safety voltage LED lighting is used to provide sufficient brightness for loading and unloading cargo inside the compartment.

Safety protection device

When the anti-collision rod touches an object or person, the equipment expands and retreats automatically for a certain distance, so as to protect the cargo and personnel.

Front control button

Control start, stop, emergency stop, lighting and other functions.

Transiton protection roller

The floating design can protect the loading and unloading personnel.

Side control button

Freely adjust the extended length of the equipment to ensure the operator moves and discharges the goods in the most suitable position.

Specification

Note: the above specifications are common sizes of shuangqi company, if you need other specifications, please contact with our sales department. Swing arm length can be customized according to customer requirements.

Optional

Man rider type Operator platform is characterized by safety and ergonomy, ftting an operator platform to telescopic belt conveyor raises one or even two operators up to the correct working height. |

Hump type

A hump device is added on the telescopic belt conveyor, which can better connect with the assembly line.

Multi-stage led tower indicator light

Used for run indication, failure indication, and stop indication.

Extra small belt conveyor

The extra small belt conveyor can be adjusted to adapt to different heights requirement.

Photoelectric sensor

Through the photoelectric effect, the belt stops and expansion stops are controlled.